新闻

from the individual form to the specific function!

Our capacitive level probes are all-rounders and are used for the measurement of bulk materials and liquids in large silos and process tanks as well as in small containers. The setting for the material to be detected is based on our proven EasyTeach philosophy and is usually handled by the pushbutton (ET), magnet (ETM), membrane keyboard (ETF) or using remote calibration (ETW). They are available with analog as well as switched outputs, and also with an IO-Link interface in future. According to the RECHNER standard, the probes consist of insulated rod electrodes as a measuring element and a connector housing that contains the electronics. Our basic technology allows an individual adjustment of all kinds of measurement and installation conditions.

A current example will show the advantages from which a system manufacturer has benefited by using application-optimised RECHNER sensors:

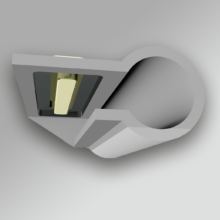

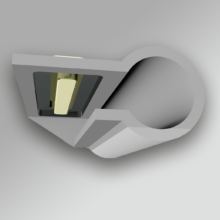

Design of a flush-installed surface sensor in a very small container, measuring electrode 40 mm x 10 mm

For the regulation of the liquid level in very small containers of a production system, our customer required a space-saving filling level measurement with high accuracy. In view of the processing of different products with different temperatures and material properties as well as the confined installation situation, this represented a challenging task.

⇒ ⇒ ⇒ ⇒

Capacitive level probes of the i-Level, True-Level and Per-Level product series

Using our rod sensors and after competent consulting, we quickly developed a miniaturised surface sensorwhose special enclosure made of a high-performance plastic allows the device to be installed in the container wall. In the context of the evaluation phase, we were able to create additional practical features with our partner, for example the possibility of a default setting implemented at the plant. With this optimal solution, our satisfied customer can now simply achieve integrated continuous filling level measurement that does not limit the container volume and precise regulation of level. The advantages for the system operator with our sensors lies in improved production quality without material loss while also requiring less energy

Do you need a sensor with maximum benefits for your application?

WE CAN DO IT

⇒ We develop YOUR sensors:

from the individual form to the specific function!